Importance of Ductility for Earthquake Resistant Structure

The past earthquake experiences in Nepal have clearly demonstrated that the typical structural design and construction methods here lack the basic seismic resistance criteria. The implementation of ductile design and detailing practices in all sorts of building construction is one of the major areas that need to be focused. The structures need to be designed to have sufficient strength and ductility for overall safety against earthquake forces.

What is Ductility?

Ductility is the ability of a material to have its shape changed without losing strength or breaking. It is therefore an indication of how ‘soft’ or malleable the material is. The ductility of steels varies depending on the types and levels of impurities present in the alloy.

For example, an increase in carbon, will increase the strength but decrease the ductility. Ductility is therefore, also termed as “the secret sauce of seismic engineering

To understand it better let’s take an example. Imagine you have taken part in a marathon. Now you have inner strength or stamina to complete the marathon. If you start to maximum energy and run as fast as you can, your energy will soon be worn out and you would probably give up without completing the marathon. Now suppose you had maintained a constant pace and picked a speed that’s comfortable with you, you would be able to burn energy slowly and probably complete the marathon successfully. If the distance is longer than what you are able to run, after some time you would probably give up.

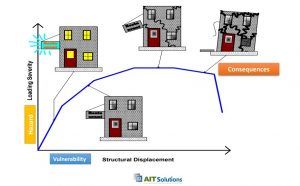

What we need to understand is, steels also have some inner ductile strength. When seismic force impact upon them, they can easily withstand what’s up to their limit. After certain exhaustion, they can deform plastically. Similarly, if the impact is sudden and high, they can reach to breaking point. This is only possible with ductile steels. The figure below illustrates, the impact of stress on buildings.

Steels made only with toughness tend to break easily on sudden seismic impact

Importance of Ductility in Steel for Constructions

- Formability: Formability of the steel refers to ability of changing the steel into desired shape without necking, breaking or cracking. During construction, the steel must be bent to different shapes by using modern technological processes like casting, molding, machining, stamping, sintering, etc. for giving particular shape or structure to the building so ductile steel is highly beneficial here.

– - Expansion: The ductility of steel also ensures that the component won’t undergo brittle fracture during work-hardening, as the energy of that process is absorbed. Steel being able to withstand extreme loads without developing cracks is quintessential for its usage in constructions.

—- - Seismic Protection: The extent to which a material can support itself during sudden seismic tremors, etc. is primary factor to be considered during construction in a seismic zone. The ductility of steel enables the structure to resist deformation due to sudden shocks or tremors and absorb the energy. If the impact energy is less than the breaking point of the steel, the energy is absorbed and damage is prevented.

——- - Tensile Strength: Tensile strength is the maximum load that a material can support without breaking or fracture when being stretched. Steels possess high tensile strength (based on the constituents of its alloy), due to minimum carbon content, and is the direct indication of high ductility. It protects the structure from sudden damage.

Steels with Ductility in Nepal

Nepal is situated in the earthquake prone zone so durability of constructions here directly relates to the use of ductile steel. Keeping this in mind and learning from great devastation during the 2015 Nepal earthquake, Rhino 500D was introduced for the first time in Nepal to exactly suit the need of earthquake resistant construction.

RHINO 500D is manufactured at state of the art automated plant, the only one of its kind in Nepal

The automation ensures uniformity in quality across every single product. The products in due course of production undergo stringent chemical and physical testing at the state of the art completely computerized labs.

This ensures instant results and faster intervention and compliance of the quality as per the NS and BIS (IS) standards

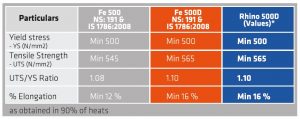

Below is the physical property of RHINO 500D.

For durable and safer constructions, there should be no second option for ductile steels. Construction with Ductile Steel mean Safety at its best. Choose best materials for long-lasting construction works.

References:

Jagdamba Steels is Nepal’s largest steel company. For a long time, that prominent business family’s conception has been in steel production and distribution. Endowed with Pollution Control Devices and ISO 9001: 2000 certification, Jagdamba is the best steel company in Nepal, producing environmentally friendly and high-quality products.