Rhino 500D

Rhino Fe500D

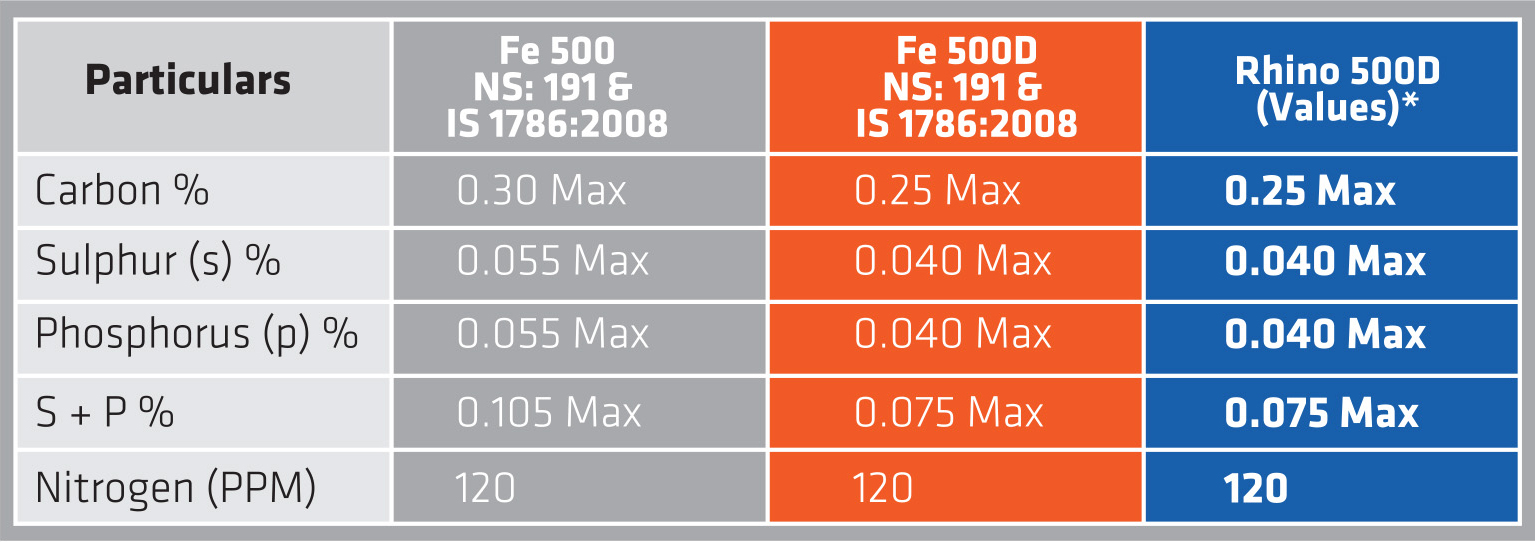

Rhino 500D is the new generation TMT rebar in Nepal with superior ductility and elongation. It is superior from other normal rebars in its method of manufacturing and combination of both mechanical and chemical properties. Rhino 500D comes with a combined restriction of impurities like Sulphur, Phosphorous and Carbon to a maximum of 0.75% and 0.25% which ensures superior ductility, elongation and strength of the rebar. Rhino 500D marks the beginning of quality benchmark for steel rebars in Nepal!

How We Fulfill Our Commitment

All of our products are manufactured at the state of the art automated plant with prime focus on maintaining highest standards in quality and make. We are the only in Nepal to follow a stringent 3 level Controlled Production Process to ensure that we only deliver World Class products.

Controlled Raw Material

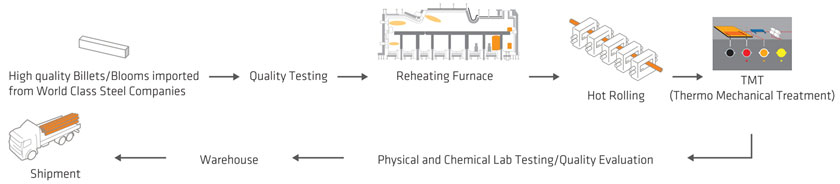

The first stage in the Controlled level of production is the ‘Control of Raw Materials’. To ensure high quality of the products, the raw materials are exclusively imported from world class steel companies like TATA Steel, JINDAL Steels, IISCO, and SAIL. Additionally, the raw materials undergo stringent quality tests at the state of the art computerized laboratory.

Controlled Production Process

All of the products are manufactured at state of the art automated plant. The one and only one of its kind in Nepal. The automation ensures uniformity in quality across every single product. The products in due course of production undergo stringent chemical and physical testing at the state of the art completely computerized labs. This ensures instant results and faster intervention and compliance of the quality as per the NS and BIS (IS) standards.

Controlled Parameters

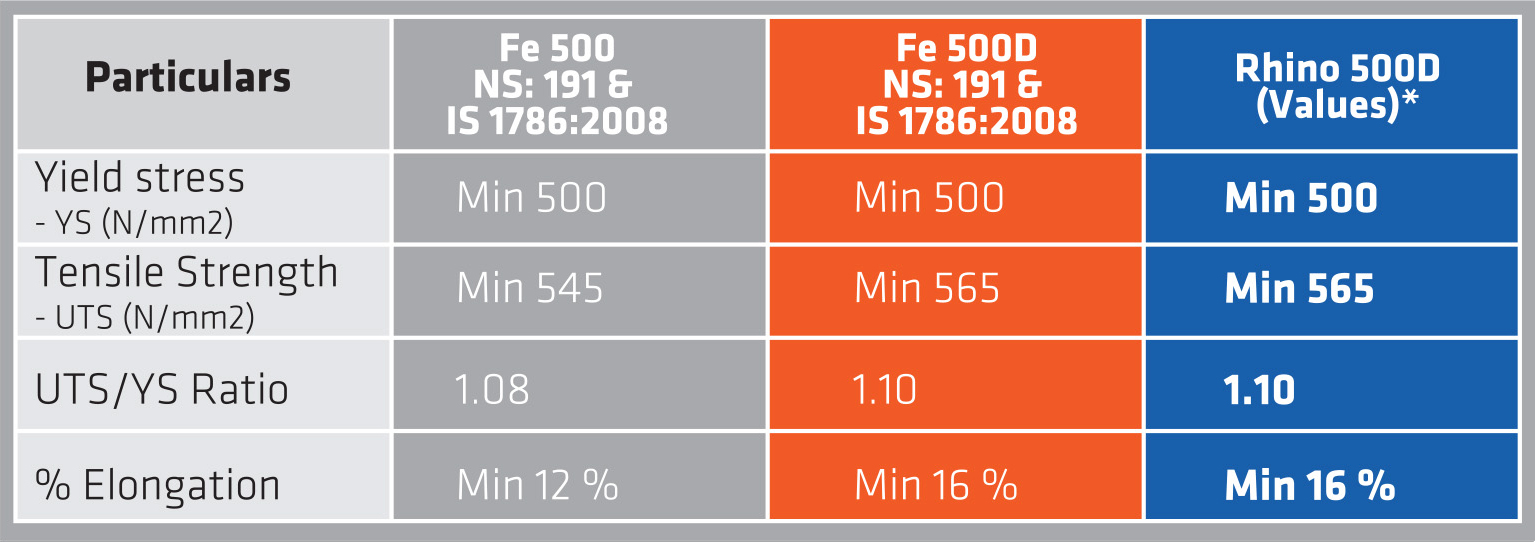

Uniformity of physical and chemical parameters is highly important to ensure superior quality of the products. This is ensured through the application of automated systems in production, and both physical and chemical testing. The physical and chemical parameters are stringently controlled and comply with the minimum and maximum standards outlined by NS: 191, Nepal Bureau of Standards and Metrology Certification Standards and Indian BIS, IS: 1786: 2008 Certification Standards for the Steel Rebar.

High Ductile Rebar; First Time in Nepal and For Nepal.

Rhino 500D Rebar is the first and the only steel TMT rebar in grade Fe 500D with superior ductility introduced in Nepal. It also marks the beginning of the New Industry Quality Benchmark for Steel Rebars in Nepal. With superior ductility and earthquake resistance properties, Rhino 500D compared to other normal grade rebars is highly suitable for applications in areas and region highly prone to seismic risks like Nepal. Rhino 500D is the only new generation rebar that truly fits in to the need of seismic resistant construction in Nepal.

Because Safety Matters! Rhino 500D Steel Rebar Matters!

As the biggest integrated steel company in Nepal, Jagdamba Steel has carried forward the challenge and responsibility of staying the very best, and in keeping with the tradition of being a leader, we have innovated and moved a step ahead now with the introduction of Rhino 500D Steel Rebars, Redefining steel making, the company has developed Fe 500D grade Rhino Rebars through the 100% special quality raw material specially imported and manufactured through automated controlled production process, quality control management route. It is the first time in Nepal that Rebars have been produced through this process to meet the changing and more stringent needs of our country and seismic zone. With High Ductility and superior earthquake resistance properties, Rhino 500D Rebar assures highest standards in quality and safety of construction and lives.

Chemistry Controls Steel Quality…We Control the Chemistry of Steel!

The chemistry and thus the properties of the Steel Bars get compromised by the presence of the harmful impurities like Sulphur, Phosphorous and Carbon, in extreme weather conditions. Through the advanced steel rebar making process the impurities are restricted in Rhino 500D Rebars to a maximum value at; Sulphur and Phosphorous 0.40%, Carbon at 0.25%. To control the chemistry we ensure the highest standard in quality of the raw materials, the billets, blooms are exclusively imported from world class steel companies like TATA Steel, JINDAL Steel and IISCO. For stronger assurance the raw materials undergo spectrometer quality testing at the state of the art automated lab before going in to production. The 3 level automated Controlled Production Process with controlled environment ensures the maintenance of the chemical and physical properties in compliance to NS: 191 and BIS (IS: 1786:2008) Certification Standards.

Superior Process and Product Quality

Why Rhino 500D Rebars are superior to traditional Rebars in the market? The answer is Superior Making and Precision in the maintenance of physical and chemical properties. Since Sulphur & Phosphorous (S&P) are harmful impurities in Steel, High level of Phosphorous can lead to ‘Cold Shortness’ in Steel a condition in which the steel tends to become very brittle under extreme cold conditions and thus highly vulnerable to cracking. High level of Sulphur can lead to ‘Hot Shortness’ in steel, a condition in which the melting point of steel gets lowered thereby reducing its strength dramatically under high temperature conditions. However, the levels of S&P can be achieved only through advanced Steel making. The low levels of S&P as specified in NS and BIS specification are impossible to achieve under normal Steel making and Rebar production process. But due to the practice of import of raw materials, the billets, and blooms from world class steel companies and manufacturing through the state of the art automated and controlled Rebar production technology and stringent quality controls at every step right from the input of the raw materials to the output, the finished Rebars comply 100% to the quality standards of Fe 500D grade specification of NS: 191 and BIS (IS: 1786:2008) Certifications.

The Process and Technology

Rhino 500D High Ductile Rebars are manufactured at the most modern rolling mill in Nepal at Simara, Bara. The Rebars are manufactured with latest ‘TMT Technology” through the 3 level Controlled Production Process to offer quality standards exceeding the NS:191 and BIS (IS: 1786:2008) certification Standards.

Applications

Rhino 500D Premium High Ductile Rebars are ideally suitable for application in areas prone to seismic risks and highly recommended for applications in construction of ranging from small individual houses to large infrastructure projects. It is ideally suitable for Nepal, considering the high seismic risk potential and the recent occurrence of the major earthquake. Ideal for:

Small Individual Homes and Critical structures in seismic zones III, IV, V

- High –rise buildings

- Bridges Flyovers Dams

- Foundation of wind turbines

- Industrial Structures Concrete Roads

- Underground Structures – Tunnels

- Thermal and hydroelectric power stations

- General purpose Concrete re-enforcement structures

5 Good Reasons why you should buy Rhino 500D TMT Rebars

- Globally Accepted Quality and highly recommended worldwide for applications in regions prone to high seismic risk. Ideally suitable for Nepal.

- Clean Steel with very low levels of impurities like Sulphur and Phosphorous.

- Guaranteed Ductility, First and only available in TMT Rebar in Nepal.

- Guaranteed Assurance in Quality.

- Fair Price and Easy Availability.

With the low levels of Sulphur and Phosphorous, the Carbon levels are maintained at much lower than the specifications which results in its excellent ductility, high strength, high bendability, better corrosion resistant and superior weldability and earthquake resistant.

The modern, automated and precision in quality control approach of manufacturing creates a combination of strength and ductility that far exceeds the minimum limit specified in the standards; NS: 191 and BIS (IS: 1786:2008). The typical values for Tensile Strength are Min 580 as against the Min 565 and elongation 18% as against 16% in the standard values. The superior values of strength and ductility is the guarantee of Rhino 500D Rebar for higher levels of safety for years.