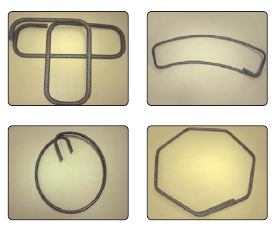

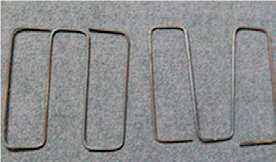

Ready Made Steels (Cut & Bend Products)

Jagdamba Ready Made Steel (RMS) customized Rebar solution customizes the lengths of rebars and bends them at required angles, in accordance with the given project’s specification. The solution caters to every kind of reinforcement requirement, redefines concepts of time and inventory management and reduces material wastage.

Why Jagdamba RMS ?

Jagdamba Steels is a pioneer in the steel industry in Nepal in terms of manufacturing technology, processing system, quality assurance and innovations. Continuing the legacy of product innovations with international standards, Jadamba RMS is the first and only of its kind of product offered by the company in Nepal.

Advantages of Jagdamba Ready Made Steel (RMS) customized Rebar Solution

Reliability

Jagdamba RMS customized Rebar Solution are made from 100% pure steel. The supply according to the given schedule is guaranteed.

Better Productivity on Site

The reduced involvement of labour in handling, cutting and bending makes site management easier and efficient. Projects can get a competitive edge due to the enhanced speed of construction.

Better Quality Construction

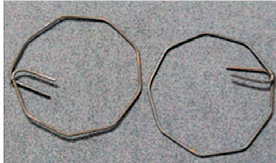

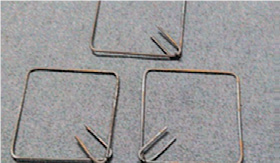

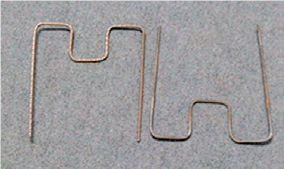

The customized Rebar solution is fully automated and the rebar’s are fabricated to NS and IS Standards. The automated machinery guarantees precision that is impossible to achieve manually. The accuracy with which the rebars are cut and bent leads to easier fabrication on site.

Reduced Wastage

Due to use of right length and bent, the wastage of material is averted, as a result the cost and hassle of disposing waste material on site is reduced.

Lesser Time for Completion

The time for the completion of the project is reduced as the products are made through process that is comparatively error free and being fully automated.

Lesser Time for Completion

The time for the completion of the project is reduced as the products are made through process that is comparatively error free and being fully automated.

Reduced Project Cost

Inventory and labour cost are reduced as the entire cut and bend process is limited to ordering the material according to specification. Wastage of material is averted as human error is done away to a large extent. Thus the cost of disposing waste material on site is also reduced.

Availability

Jagdamba RMS is available in standard sizes as following and can be customized as per the requirement.

- 8MM

- 10 MM

- 12 MM

Quality Assurance with Jagdamba Steels

- Raw material in pure steel form is used in manufacturing all steel products.

- Automated stringent physical and chemical quality check of raw materials are performed continuously from Pre- Production, Production to completion of Production.

- Computerized Physical and Chemical test labs ensure faster and accurate results, reducing any chances of human error.

- Computerized weighing and tamper proof labeling system to ensure accurate weight and quantity in each set.

- Digital delivery processing system for faster, efficient and timely delivery.

- All products manufactured to stringent NS and IS Standards.