Galvanized Wire | Jagdamba Steels

GALVANIZED WIRE

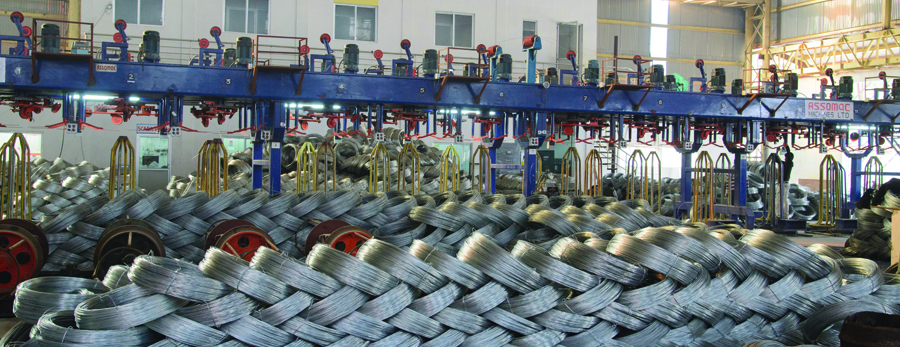

While manufacturing G.I. Wires(GALVANIZED WIRE), annealing, picking procedures are mostly carried out. Following the high-tech methodology, G.I. Wires are produced through H.B. Wires in Nepal. Galvanizing methods are dome with 99.9 percent pure electronic zinc. Prior to galvanizing, the activities like pickles and rinse are carried out thoroughly and flex coating is applied in the wires which helps zinc to stick in the base metal effectively. With the quality recognition of IS 4826/1979 and NS 163,165/ 645. Jagdamba has been manufacturing G.I. Wires.

Following tests are carried out in wires:

- Measurement of Zinc coat

- Equality of Zinc coat

- Stickiness of Zinc coat

- Tensile strength

- Wrapping test

Quality Assurance

To ensure our valued customers continuously with the quality through the strategic utilization of innovative technology, skilled manpower and available sources is the major aim of our quality assurance. We are committed in bringing the changes in line with the changing needs and aspirations of our valued customers along with the betterment of cooperation among all the staffs associated with the company.

Hard Black Wires (H.B) as per NS 169-2045

TOLERANCE UNITS

| Size | Tolerance (mm) |

| Up to 0.25 | 0.010 |

| Over0.25 to 0.50 | 0.015 |

| Over 0.50 to 1.0 | 0.020 |

| Over1.0 to 1.5 | 0.030 |

| Over 1.5 to 2.5 | 0.040 |

| Over 2.5 to 5.0 | 0.050 |

| Over 5.0 | 0.060 |

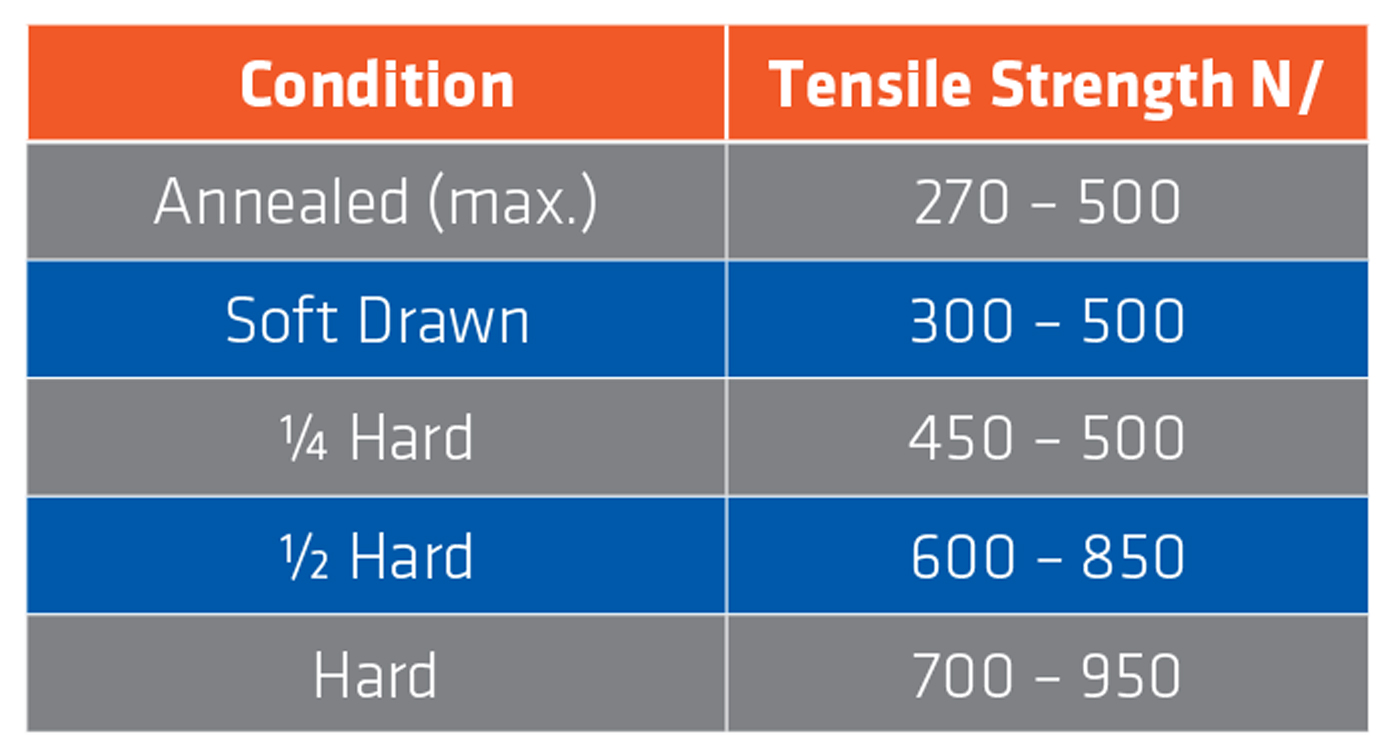

TOLERANCE STRENGTH

| Condition | Tensile Strength N/ |

| Annealed (max.) | 270 – 500 |

| Soft Drawn | 300 – 500 |

| ¼ Hard | 450 – 500 |

| ½ Hard | 600 – 850 |

| Hard | 700 – 950 |

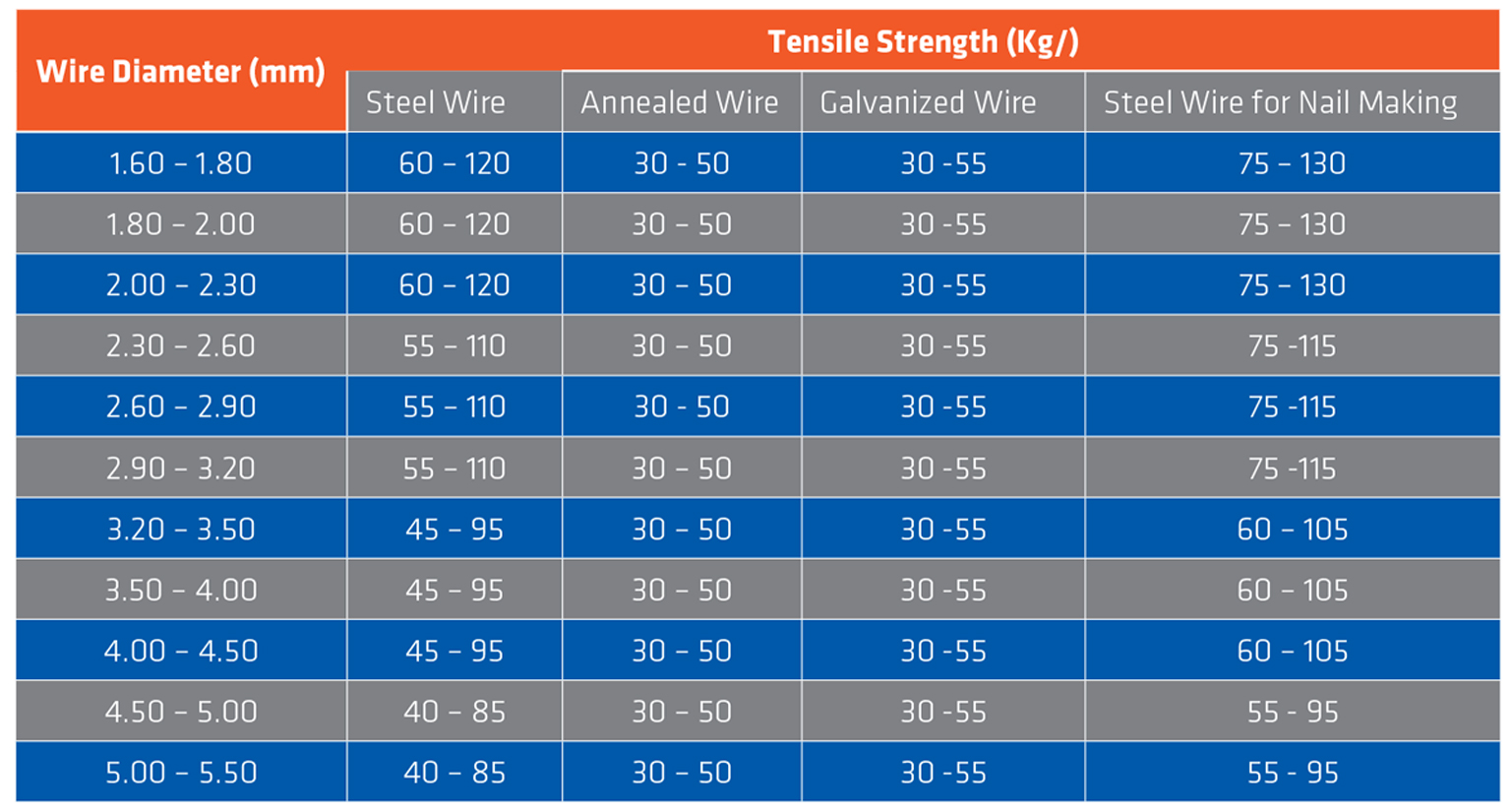

Tensile Strength (Low Carbon Steel Wires)

| Wire Diameter (mm) | Tensile Strength (Kg/ ) | |||

| Steel Wire | Annealed Wire | Galvanized Wire | Steel Wire for Nail Making | |

| 1.60 – 1.80 | 60 – 120 | 30 – 50 | 30 -55 | 75 – 130 |

| 1.80 – 2.00 | 60 – 120 | 30 – 50 | 30 -55 | 75 – 130 |

| 2.00 – 2.30 | 60 – 120 | 30 – 50 | 30 -55 | 75 – 130 |

| 2.30 – 2.60 | 55 – 110 | 30 – 50 | 30 -55 | 75 -115 |

| 2.60 – 2.90 | 55 – 110 | 30 – 50 | 30 -55 | 75 -115 |

| 2.90 – 3.20 | 55 – 110 | 30 – 50 | 30 -55 | 75 -115 |

| 3.20 – 3.50 | 45 – 95 | 30 – 50 | 30 -55 | 60 – 105 |

| 3.50 – 4.00 | 45 – 95 | 30 – 50 | 30 -55 | 60 – 105 |

| 4.00 – 4.50 | 45 – 95 | 30 – 50 | 30 -55 | 60 – 105 |

| 4.50 – 5.00 | 40 – 85 | 30 – 50 | 30 -55 | 55 – 95 |

| 5.00 – 5.50 | 40 – 85 | 30 – 50 | 30 -55 | 55 – 95 |

Minimum weight of Zinc coating per unit surface of uncoated wire as per NS 163/ 169 – 2045

| Gauge | Diameter (mm) | Light Coating ( gms/ ) | Medium Coating (gms/ ) | Hard Coating (gms/) | ||

| Soft | Hard | Soft | Hard | |||

| SWG 6 | 4.877 | 130 | 100 | 155 | 290 | 270 |

| SWG 7 | 4.470 | 130 | 100 | 155 | 290 | 270 |

| SWG 8 | 4.064 | 130 | 100 | 155 | 290 | 270 |

| SWG 9 | 3.658 | 120 | 90 | 135 | 280 | 260 |

| SWG 10 | 3.251 | 110 | 80 | 135 | 270 | 250 |

| SWG 11 | 2.946 | 100 | 70 | 120 | 240 | 250 |

| SWG 12 | 2.642 | 90 | 70 | 120 | 260 | 230 |

| SWG 13 | 2.337 | 80 | 70 | 110 | 260 | 230 |

| SWG 14 | 2.032 | 80 | 60 | 105 | 240 | 210 |

| SWG 15 | 2.032 | 80 | 60 | 105 | 240 | 210 |

| SWG 16 | 2.032 | 80 | 60 | 105 | 240 | 210 |

Tolerance on wire diameter of NS 163, 169/ 045 light, medium, and heavy coated galvanized low carbon wire are + 2.5%

UNIFORMITY TEST (for low carbon G.I. Wire) as per NS 163/ 169 – 2045

| Gauge | Light Coated G.I.Wires Uniformity Test No. of dips | Medium Coated G.I. Wires Uniformity Test No. of dips | Heavy Coated G.I. Wires Uniformity Test No. of dips | |||||||

| Soft | Hard | Soft | Hard | |||||||

| 1 min | ½ min | 1 min | ½ min | 1 min | ½ min | 1 min | ½ min | 1 min | ½ min | |

| 6 | 2 | – | 1 | 1 | 2 | – | 3 | 1 | 3 | 1 |

| 7 | 2 | – | 1 | 1 | 2 | – | 3 | 1 | 3 | 1 |

| 8 | 2 | – | 1 | 1 | 2 | – | 3 | 1 | 3 | 1 |

| 9 | 1 | 1 | 1 | 1 | 1 | 1 | 3 | 1 | 3 | – |

| 10 | 1 | 1 | 1 | – | 1 | 1 | 3 | 1 | 3 | – |

| 11 | 1 | 1 | 1 | – | 1 | 1 | 3 | 1 | 3 | – |

| 12 | 1 | 1 | 1 | – | 1 | 1 | 3 | – | 2 | – |

| 13 | 1 | 1 | 1 | – | 1 | 1 | 3 | – | 2 | 1 |

| 14 | 1 | – | – | 1 | 1 | – | 3 | – | 2 | – |