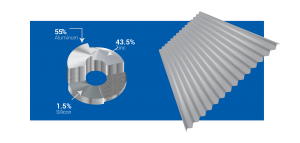

Jagdamba Galva+, Al – Zinc Coated Sheet also known as GALVALUME, is a steel sheet with a coating consisting of 55% aluminum, 43.5% zinc and 1.5% silicon over the base metal to protect it from the elements. This coating has superior corrosion resistance which gives it two to four times the life span over traditional galvanized metal. Jagdamba Galva+ is a new benchmark/ quality standard in the advanced roofing industry in Nepal created to protect metal (primarily steel) from oxidation using Al-Zn Coating. Therefore, aluminum is what differentiates Jagdamba Galva+ from normal Galvanized steel available in Nepalese market.

JAGDAMBA GALVA+ PROCESS: GALVALUME LINE

The line offered is supplied with an ECL (Electrolytic Cleaning) section which uses alkali solution to clean the strips or any oil residue coming from the cold rolling mill.

The next section is NOF (Non-Ox) Furnace to produce the complete range of soft, semi-hard and full hard coated steel. The furnaces have a direct fired section using LPG burners to bring the strip temperature up to 800 degrees Celsius. The furnace also has an electrically heated holding section required to anneal the strip. The strip passes into the hot-dip induction pot which contains the molten aluminum and zinc alloy.

The aluminum and zinc pre-alloy is made in the pre melt induction pot and is poured through a launder into the main induction pot where the strip is coated. The coating weight is controlled by the accurate air knife system.

The line is equipped with in-line tension levelling equipment and skin pass mill to maintain absolutely flat strip surface and uniform finish before color coat operation.

The line also features chemical coater to coat the strip with organic coating to prevent the strip against white rust.

Jagdamba Super Shine is a premium Al-Zn color coated Sheet that is elegant and beautiful with same features as of Galva+ coated with superior paint technology that provides additional protection for longer life.

Jagdamba Super Shine is a premium Al-Zn color coated Sheet that is elegant and beautiful with same features as of Galva+ coated with superior paint technology that provides additional protection for longer life.

BENEFITS OF JAGDAMBA SUPERSHINE

Nepal’s First Fully Automated New Advance Galvalume Line Technology

Jagdamba Steels is the first new Al-Zn coated product manufacturer of Nepal’s first fully automated advance Galvalum line manufacturing process. The manufacturing of Jagdamba Galva+ Sheets includes latest global technology and the best machinery process. Electrolytic Cleaning, NOF (Non-Ox) Furnace, In-Line Tension Levelling Equipment and Skin Pass Mill to name a few to ensure the highest level of safety, long life and beauty for your home.

Durable and Corrosion Resistance

The primary benefit of Jagdamba Galva + is corrosion resistance. Jagdamba Galva+ comes with Anti – Corrosion Technology which is the results of ACRYLIC COATING done in Galva+ that prevents early corrosion of steel and substantially increases the life of the roof.

The addition of aluminum increases the coating’s corrosion resistance by a factor of two. If the steel panel is in an area where heavy salt-spray and high humidity predominate, Galva+ provides the most robust protection.

Aluminium -Zinc Coating

Al-Zn coated Jagdamba Galva+ products offer superior corrosion resistance compared to other coating technologies making your roof last longer even in the harshest of weather conditions.

All Weather Protection

Jagdamba Galva+ withstands all kinds of weather be it heavy rains, humid coastal areas, cold snow areas or heat. Jagdamba Galva+ Steel coated with Al-Zn also has superior reflectance in the sunlight. High reflectance reduces heat absorption through the roof panels. With the addition of re-emissive pigments, you will have both energy efficiency and protection from corrosion. With appropriate insulation under the roof, you will reduce cooling costs in the summer and heating costs in the winter. Galva + is also RESISTANT TO HIGH TEMPERATURES.

Strength

Jagdamba Galva+ does not add significant weight to the steel, retaining the metal’s high STRENGTH-to-weight ratio. The coating is every bit as strong and durable as the steel itself. The coating is flexible and will not crack or flake as the sheet metal is bent or formed.

Superior Paint Technology

Jagdamba Super Shine, premium color coated sheets, uses a superior paint technology known as REVERSE & FORWARD COATING METHOD and GFG Coates in Jagdamba Galva+ that provides additional protection for longer life. The superior paint technology resists cracking and peeling even of paint. Ordinary paint starts fading very fast and in 1-2 years the roof starts looking dull and old. It ensures that the roof looks new for many years providing additional beauty to your house.

Stringent Quality Test

Jagdamba Galva+ and Jagdamba Super Shine goes through more than 10 + and 15+ respective stringent quality tests. PHYSICAL and CHEMICAL test, 360 DEGREE BENDING test, Adhesion test, ANTI FINGER COATING test and ONLINE QUALITY INSPECTIONS to name a few to ensure best quality product is supplied to our valued customers.

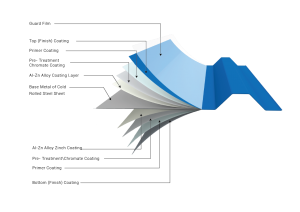

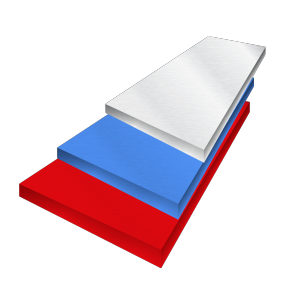

Guard Film Coated

The Jagdamba Supershine features 8 Layers of protection. The top and bottom are layered with 4 layers each to ensure longevity. The layers have been carefully crafted to ensure the best quality available in Nepal. A Protective Guard Film is applied to Jagdamba Supershine’s topcoat layer to prevent possible damage during handling and storage.

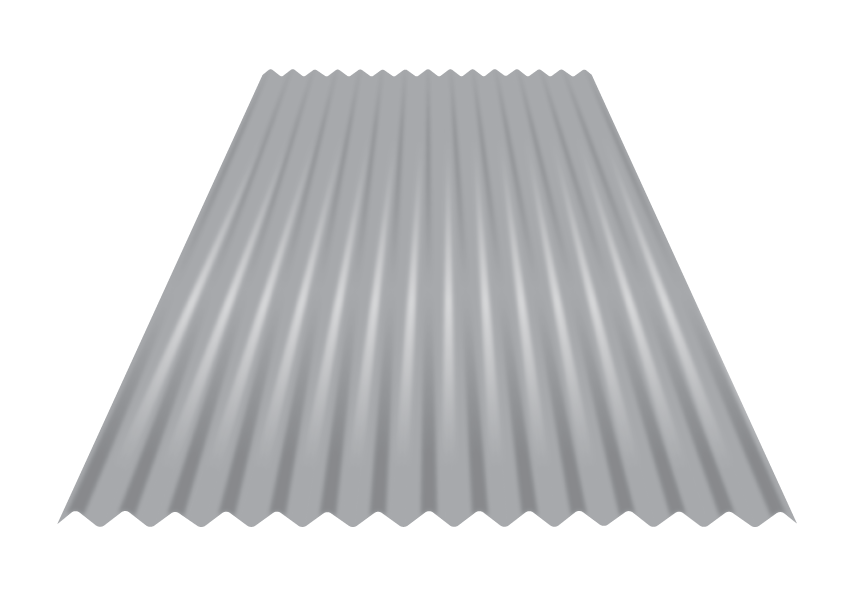

Proper Corrugation Overlapping

The Jagdamba Galva+ and Jagdamba Supershine’s proper groove finishing makes it easier during installation and prevents the roof from leaking.

Proper Packet Packaging

To ensure that our product reaches our consumers in a well-packed condition from our retail outlets, Jagdamba Galva+ and Jagdamba Supershine are well-packaged so as not to suffer any physical damage during delivery.

Eco Friendly Material and Manufacturing Process

Jagdamba Galva+, Premium AL-ZN Sheet and Coils, is made out of 55% aluminum, 43.5% zinc and1.5% silicon by weight. This means that the composition creates a durable and reusable rooftop providing you with robust protection from humidity or any kind of harsh weather and corrosion. This product passes through salt spray test and archive more than 800hours, however in case of Galvanizing it is only 72 hours.

APPLICATIONS

- Roofing and siding applications

- Unexposed automotive parts

- Appliances

- Furniture

- Outdoor cabinetry

- Computer cases

- Gutters

- Pipes

FUNDAMENTAL PRODUCT STRUCTURE OF JAGDAMBA SUPER SHINE

Our Color Coated Jagdamba Super Shine Corrugated Sheets are manufactured using Prepainted Al-Zn color coated sheets as the raw material, combined with a high quality, suitable and economical paint. With imported production lines, we are able to produce adequate amount of steel corrugated sheets as aesthetics, good quality and economical light weight, high strength product to satisfy large scale market demands as well as to model your dream structure. Our Trapezoidal Profile is excellent for Roofing and Cladding.

|

SN |

Specifications |

Lengths |

|

1. |

Total PPGL Sheet widths |

885mm |

|

2. |

Total Profile Widths |

800 ± 5mm |

|

3. |

Coverable widths |

760 ± 5mm |

|

4. |

Pitch Width T/S |

75 ± 2mm X 10 |

|

5. |

Pitch depths |

18 mm (±1.5mm) |

|

SN |

Specifications |

Lengths |

|

1. |

Total PPGL Sheet widths |

1000 mm |

|

2. |

Total PPGL Heritage Widths |

860 ± 10 mm |

|

3. |

Total PPGL Coverable Heritage widths |

740 ± 10 mm |

|

4. |

Pitch |

89 mm |

|

5. |

Collar both side |

25 mm |

|

SN |

Specifications |

Lengths |

|

1. |

Total PPGL Sheet widths |

1220 mm |

|

2. |

Total PPGL (H- Span)Trapezoidal Widths |

1060 ± 10 mm |

|

3. |

Total PPGL (H- Span) Coverable widths |

1000 ± 10 mm |

|

3. |

Big Pitch Width |

198 mm |

|

4. |

Collar (One Side) |

20 mm |

|

SN |

Specifications |

Lengths |

|

1. |

Total Barrel Sheet widths |

885 mm |

|

2. |

Total Profile Widths |

800 ± 5 mm |

|

3. |

Coverable widths |

760 ± 5 mm |

|

3. |

Pitch Width T/S |

75 ± 2 mm X 10 |

|

4. |

Pitch depths |

18 mm (± 1.5 mm) |